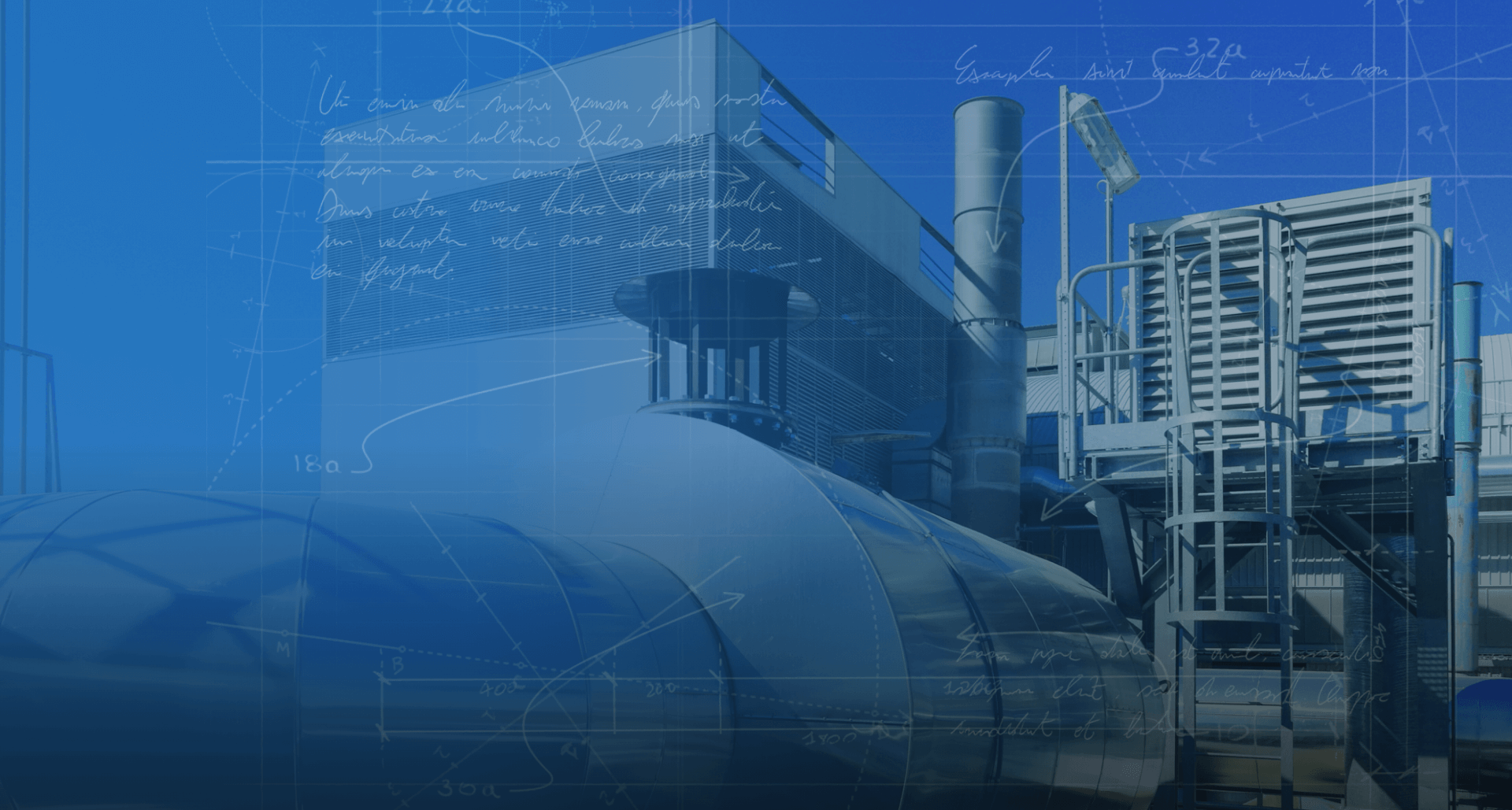

CTM Ambiente

Soundproofing systems and acoustic design

for industrial applications

Customized solutions for machine and plant noise reduction

CTM Ambiente specializes in design, supply and installation of acoustic solutions for noise attenuation in industrial environments of all sectors, contexts and sizes.

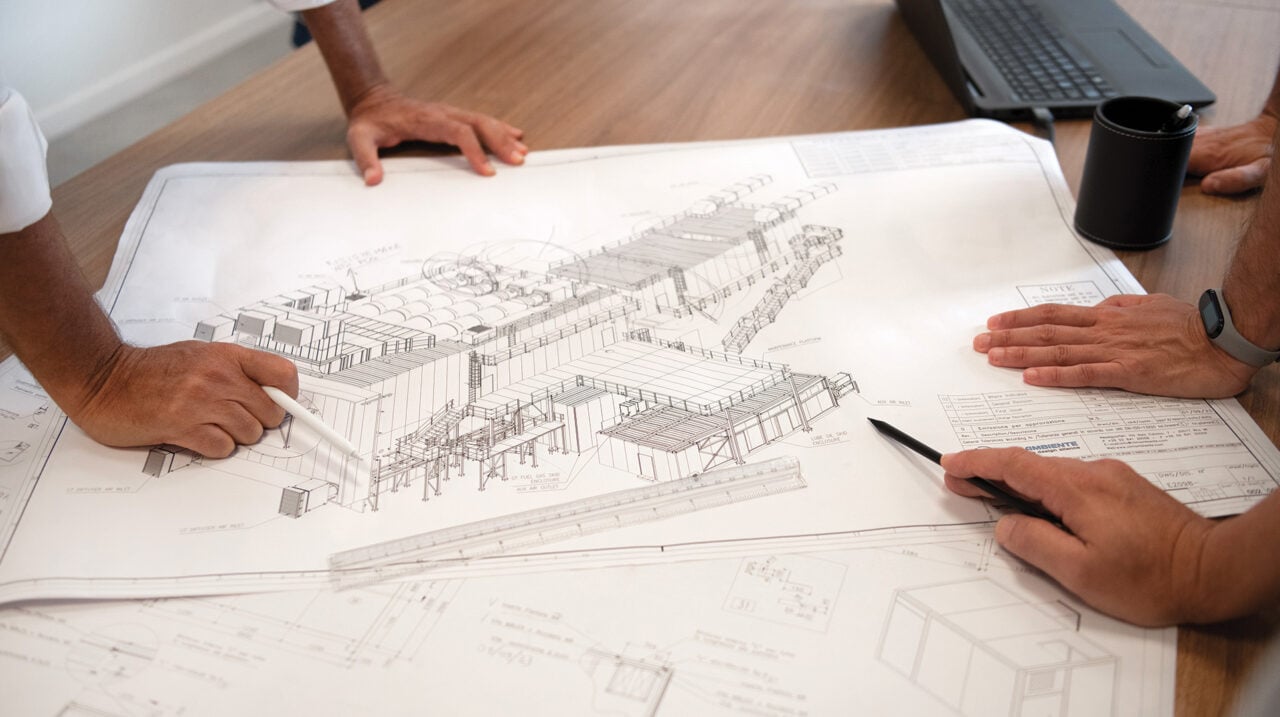

The company

30 years of experience and specialization

CTM Ambiente is a company with well-established engineering know-how that has been operating for decades in the field of industrial soundproofing, assisting companies in various sectors – energy, Oil&Gas, marine, civil, chemical, food, etc. – in their specific noise abatement requirements .

To satisfy our customers, we focus on the specialized skills of our team, on technological instrumentation state-of-the-art and on a certified quality management system.

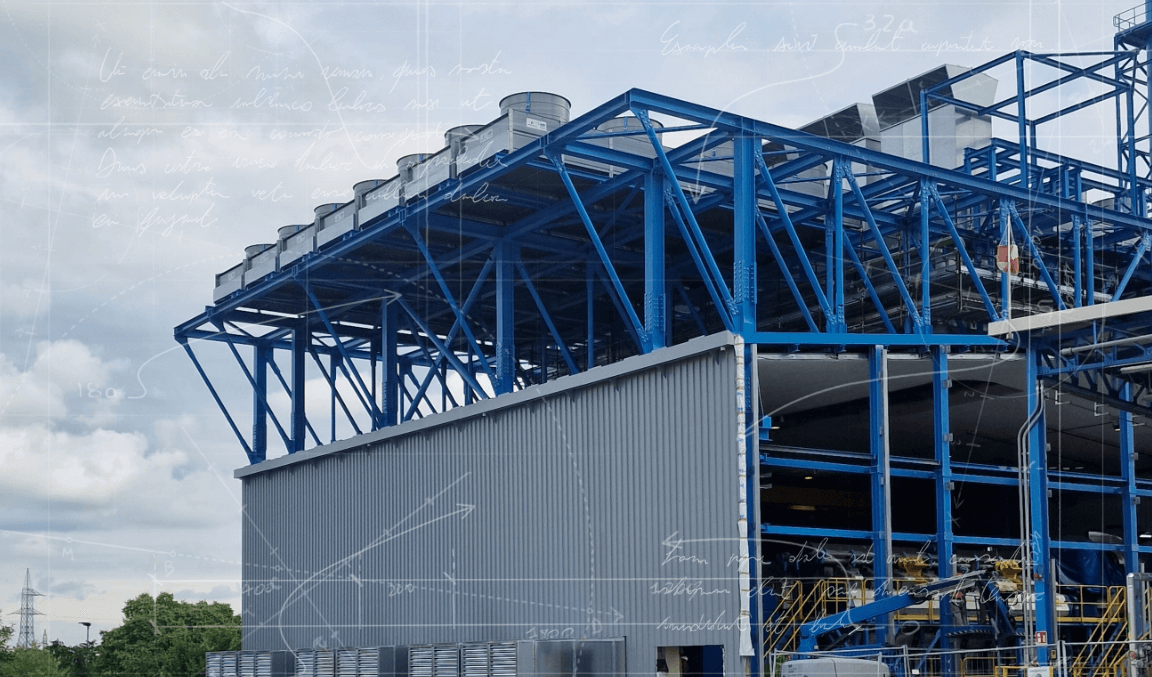

Accomplishments

Discover our projects around the world

Our anti-noise solutions know no boundaries. Over the past 30 years, we have developed and installed silencers, sound barriers, soundproof booths and rooms, and other ad hoc devices on all continents, accepting the many challenges of the particular contexts of application and use, from desert climates to offshore platforms.

Acoustic consulting

Surveys, mapping, investigations, testing: a full service

CTM Ambiente offers a 360-degree consultancy for the treatment of noise sources in any context, addressing to its clients a wide range of acoustic services fundamentals: forecast calculations, environmental impact reports, phonometric surveys, noise analysis and monitoring, and other services preparatory to targeted noise mitigation interventions.